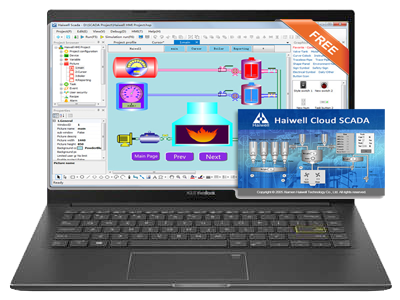

Haiwell Cloud SCADA Software

● Integrated data-link tool

* Through Haiwell data-link tool, real-time data and historical data can be stored in databases such as MySQL and SQL Server, and data can be delivered.

● Support MQTT protocol & built-in MQTT server

* Support MQTT protocol, support access to database server, easily realize data collection and reporting, and connect to ERP/MES etc. The built-in MQTT server can enable proxy function and easily implement MQTT net-working.

● Cloud transparent transmission function

* Remote programming, upload&download, firmware upgrade, diagnostics, monitoring and debugging of PLC programs. Detect abnormal conditions on the spot anytime, anywhere.

● Support for secondary configuration

* The variable data can be flexibly invoked to achieve centralized control of off-site equipment, making it easier for engineers to remotely control centrally.

● Remote access control

* It can be monitored by browser of any networked computer. The phone screen is the same as the PC, no need of repeat configuration.

● Haiwell Cloud data center

* No need for users to build MQTT server, easily achieve remote centralized control of equipment through Haiwell Cloud data center

● Programmable command language

* Supports JavaScript programming language, more powerful than traditional SCADA and all configuration resources will be more fully utilized.

● Rich alarm notification

* The alarm information of the industrial site will be timely notified to the relevant staff through the form of screen, computer voice, WeChat, SMS, and mail.

● Supports multiple third party protocols

* Built-in a variety of industrial equipment drivers, supports the current mainstream PLC, inverter, instrument

● Powerful displaying function

* The industrial site condition can be observed directly to do real-time monitoring through the various primitives and bitmaps of the picture.

● Powerful Connectivity

* Communicate with all kinds of industrial control equipments, monitor by acquisition of production signal from the industrial site.

● Rich function modules

* The alarm notice about the industrial site can be sent by picture,computer voice,Wechat,,SMS, mail, ect to the relevant personnel.

● Strong Database

* Record and store data. Make an analysis of real-time data and historical data to solve the production problems, improve production efficiency and improve product quality, etc.

● Programmable command language

* Provide to the user with the JavaScript programming language function.

● System Security

* Avaliable to set security control level for project(such as security level, user level,etc), which can improve the security of the project.

● Simulation function

* Available to run in simulation, which ensures the project not to be affected by the actual devices. And it can be tested in the software, shortening the development cycle.